I do not believe that thicker emulsion gives thicker coatings, because the squeegees i use squeeze the mesh between the squeegee and the shirt.

True, with some additions.

We are talking about dealing with screen printing - that is flexible squeegee, flexible mesh, and flexible stencil...

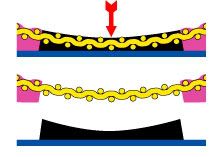

Now we have the “Rope Bridge Effect (c)”

The more open the print area the more likely the squeegee is to flex down to the substrate and touch the substrate - this is why screen printing always gives us the “smile” or concave layer of ink.

Now consider adding “pillars” of emulsion - what we get with halftones and detailed patterns - now we have the second item come into play -

the effects of surface tension and liquids the smaller the area of ink the more likely that this comes into play and we get “droplets” that tend to form a dot or dome shape, if the substrate is absorbent this effect will be negated to some extent particularly with water based inks on fabric less with plastisol.

Viscosity plays a part in this also - smaller dot, higher viscosity, more effect with surface tension. (We also have pressure deformation but that comes later after the transfer of ink.)

Now before I go much further with anything...

I am not attacking you or your posts - please understand this, I am simply pointing out some HS level science applied to the process of screen printing.

I may not be from Missouri but I understand “show me” I am more than happy to be wrong and to change, the value of my material is not in the material or my connection to it but only if it is fact and is applicable - I only care about facts and application the content has to follow that, I don’t care nor do I have an interest in promoting a POV or product unless it fits.

My job is to search answers, study screen printing, fix things for clients and then show that in a form to people so that they can work more effectively and profitably in their business.

When I am wrong, that adds more information I can use to present to more screen printers and make things better for at least one more person - and when I say tears, I am dead serious about that, more than a few times I have come across tears of frustration - and I understand, I have been there myself.

I consider the bad and wrong things in my background the

MOST valuable it seems that education works best and is most memorable when some pain is involved.

Where I differ from most is that I simply cannot just take information - it must be fact, it must be testable, it needs to be in a form that can be tested simply and it must be repeatable. Also stacking a test in favor of a result is without value, it may show the same answer but it also shows an agenda, my agenda is simply “the little guy” the advancement of the industry out of the stoner-hippie troglodyte stage into the light of some form of "enlightenment era” where we value facts and results and not pushing a product for profit at the expense of “the little guy.”

Who advocates for “the little guy?"