To add to this good advice it's important to know that emulsion viscosity and solids content and resulting EOM may require evaluating your scoop coater edge and number of coats as well as the type of mesh you are coating.

Sharp Edge: Higher Viscosity, higher solids content, sharp edge as a general rule. Higher mesh counts above 200 and especially above 300. Murakami T9 for example is a high viscosity, high solids emulsion. 1:2 sharp below 200, 1:1 sharp above 200. Also a slower coating speed is recommended. S-mesh sharp edge and only 1:1 sharp coating with Murakami T9 on all mesh counts.

Dull Edge: Lower viscosity, lower solids. 1:1 dull to 1:2 sharp. 1:2 dull below 200, 1:1 dull or 1:2 sharp above 200. Too often when switching emulsions from diazo to a pure photopolymer companies stick with the same coating technique. A 1:2 dull used on a diazo emulsion may yield 6-10% EOM, but with a pure photopolymer it can jump to 15-20% EOM and make details hard to capture.

A thickness gauge is an important tool to quantify the coating process. Once determined with or without a thickness gauge all personnel should use the same method to avoid differing EOMs that will change exposure quality. One person's coating could be too thick, one could be too thin. The end cap should be close to the mesh when coating. If one person lays the coater over, and one person scraps the emulsion at a vertical angle, durability on press, pinholes, over or under exposure will cause exposure times to be chased. This is crucial on LED where there is little window of latitude in the exposure. An over coated screen heading for discharge would be underexposed at established times due to much emulsion and lack of exposure on the inside.

In all cases above, the easiest verification of coating is with a thickness gauge, you can also use a Stouffer 21 hardness scale on every exposure. This would tell you that the 110's coated by morning crew are fine and hitting a hard 7, but night crew is hitting only a hard 5 or 6 at night with their coating. Good time to review morning and night shift coating techniques.

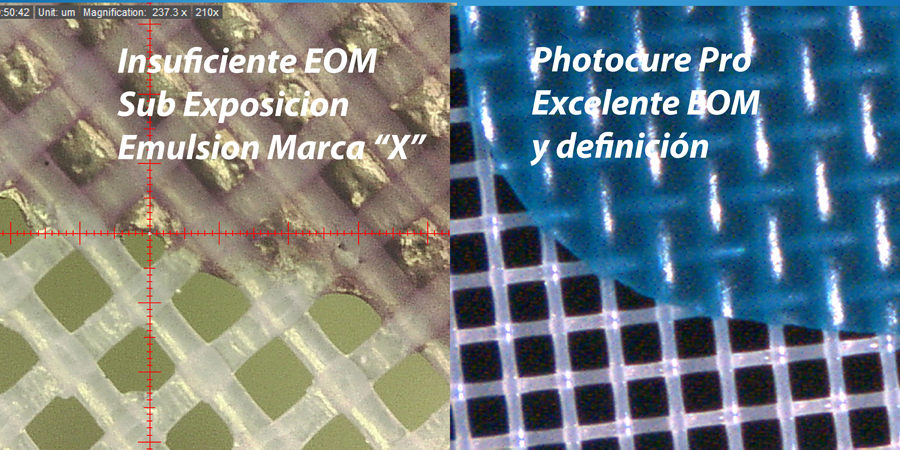

The photo below is from a seminar I give at my dealer in Mexico City, Improper EOM left, poor edge definition 0% EOM, Good EOM right, excellent edge definition 10% EOM (spot color). For halftones I recommend 6-7% maximum.

Stay well,

Al