The first dividing line of densitometers is between "transmissive light" or "reflected light". For working with film, you want a transmissive densitometer in order to read "film density". Reflective light densitometers are used for printing which used "Ractive Coated (RC) paper, which is similar to a printed photograph (rather than the film negative). Reflective densitometers can also measure printed products.

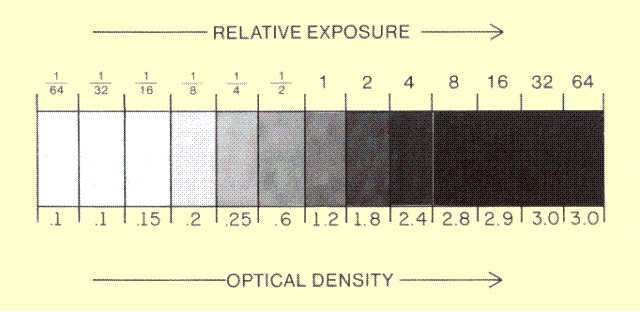

When a densitometer reads film or RC paper, there are 2 basic measurements it makes. The densitometer can read absolute density. For most practical purpose, a density of 3.0 is more than is needed. Density can go beyond 3.0, at 3.0 density you can watch an eclipse of the sun through the film, with the sun clearly visible through the film.

Densitometers also will either measure they film density in visible light or UV light (like the exposure unit uses). Silver based film was very consistent in light blocking across a wide range of spectrum's. Inkjet ink might not translate as well between spectrum, so a densitometer which actually tests in the UV spectrum could be used to test the spectral density of the inkjet ink.

The other purpose of a densitometer is to measure halftone percentage. Depending on what LPI the halftone screen is, the densitometer has "aperture" inserts, so a aperture with bigger hole would be used to measure courser halftones, while smaller aperture are used to measure finer lpi halftones. When shopping on ebay, be sure you get these otherwise you'll have to track them down and will be more expensive than they should be. While on what to look for on ebay, be sure the densitometer has its book and "calibration target". The calibration target is used to calibrate just what a density of 3.0 means, because a known standard was used as the basis of definition. When you change aperture, you need to recalibrate

In the printed book world, i lived and died on the densitometer. The density of the film/RC paper was maintained at a baseline standard. By affixing a standard, a control is established, that film can be ruled out as the cause of any problem. Bad film, a broke water heater or any number of other things could easily be identified by simply testing the film density. Inkjet film is different. The primary cause of problem is clogged inkjets. I don't need to see a density reading to look at film and see there is a clogged jet. The outside marks alone will show me breaks. So buying a densitometer, just to monitor the density of film is low on my list of things i need to spend money on.

The other purpose of density control is to calibrate halftones. By performing a reflective reading on a printed product, the actual halftone dot printed will be measured. The art called for a 50% halftone, but the shirt has a 60%. In order to get these reading for anything other than b&w, you need a color densitometer, which maybe a second and separation densitometer than the one you use for film. Knowing the print is 10% dark, a "transfer curve" can be defined in the rip, so that a 50% screen will print to film as a 40% screen, so when it prints and has press gain, the 40% turns back into the 50% the artwork was designed with.

Now in a perfect world, you'd also have a densitometer which worked on your computer monitor. Then the color you see on the screen will look the same as the color you print.

What the densitometer does, is give an objective value to what is being viewed.